Measure for Quality

Thorough Quality Management until Product is Made

We have “a quality assurance team” specialized in product quality management.

This team is involved in product development from the initial product planning phase, which

is managed by our development team, to provide objective eyes through inspections.

01Preliminary Verification

The first verification before deciding whether or not to commercialize the product.

The purpose is to see if the product performs as per the specifications, is safe to use, or possesses any design faults

For example, for “a new concept of an easier-to-hold handle shape”, we inspect to ensure the handle doesn’t heat up when on a stove, and the product remains stable when placed on a gas hob.

In addition to the design, we inspect that the product from the perspective “is it truly safe when in actual use”? to ensure the fundamental safety before the product is put on the market.

If there is any concern for performance or safety, we repeat improvement efforts until the product is ready for the market.

02Verification

Inspection and verification based on various quality criteria to take place after the decision to commercialize the product.

Product samples close to completion are verified both internally and by a third party.

Samples are subjected to inspections, including: “Inner-coating performance” inspection to verify the scratch resistance and coating inside the pan. Inspection to verify its “resistance against breaking” when the glass lid is dropped. “External-surface discoloration test” to verify how easily the coating discolors. “Design check” to verify if the specifications make the product difficult to use. We perform multiple inspections to verify safety and use the products to test them according to WIS from our customers’ perspectives.

Samples near their finished forms are subjected to these verifications, and depending on the results, are modified for improvements.

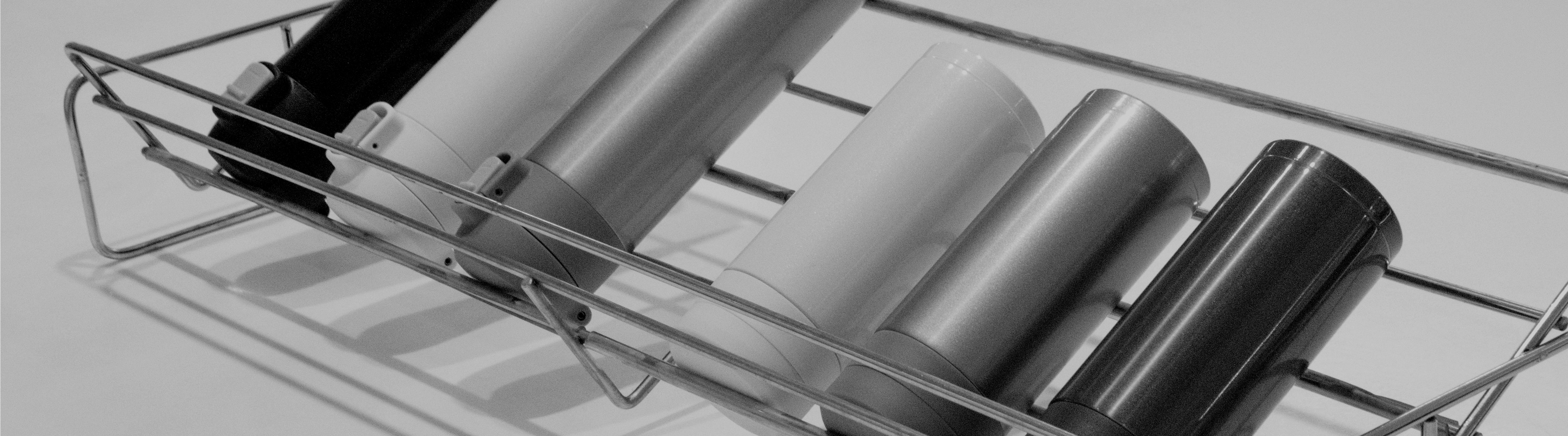

03Shipping Inspection

This inspection takes place at our manufacturing plants.

At the plants, products are inspected to confirm that their thickness and size are consistent with their specifications, without any dangerous scratches or cracks, to ensure safe products are being manufactured.

Our overseas plants also perform strict inspections according to the Wahei Freiz criteria. In some cases, our Japanese inspectors visit the overseas plants for observation, and quality is exhaustively controlled regardless of the manufacturing location.

04Acceptance Inspection

This is the final inspection to take place when products are received at the warehouse in our Niigata headquarters.

Not only the first article but also repeatedly-delivered products are inspected every time. Information on defects is shared among relevant departments, and feedback is sent to the plants for improved production quality.

Inspections are performed using inspection sheets to ensure products are produced according to the manufacturing specifications without any scratches or contamination, and there have been no issues during transport from the plants.

To Offer Better Products

We are committed to regulatory and official standards as well as to WIS to provide high-quality products with improved safety, reassurance, and peace of mind through the 4-stage quality control: “before the decision to commercialize”, “after the decision to commercialize”, “pre-shipping” and “warehouse acceptance”.